The Lucrative Business of Propane Tank Refilling

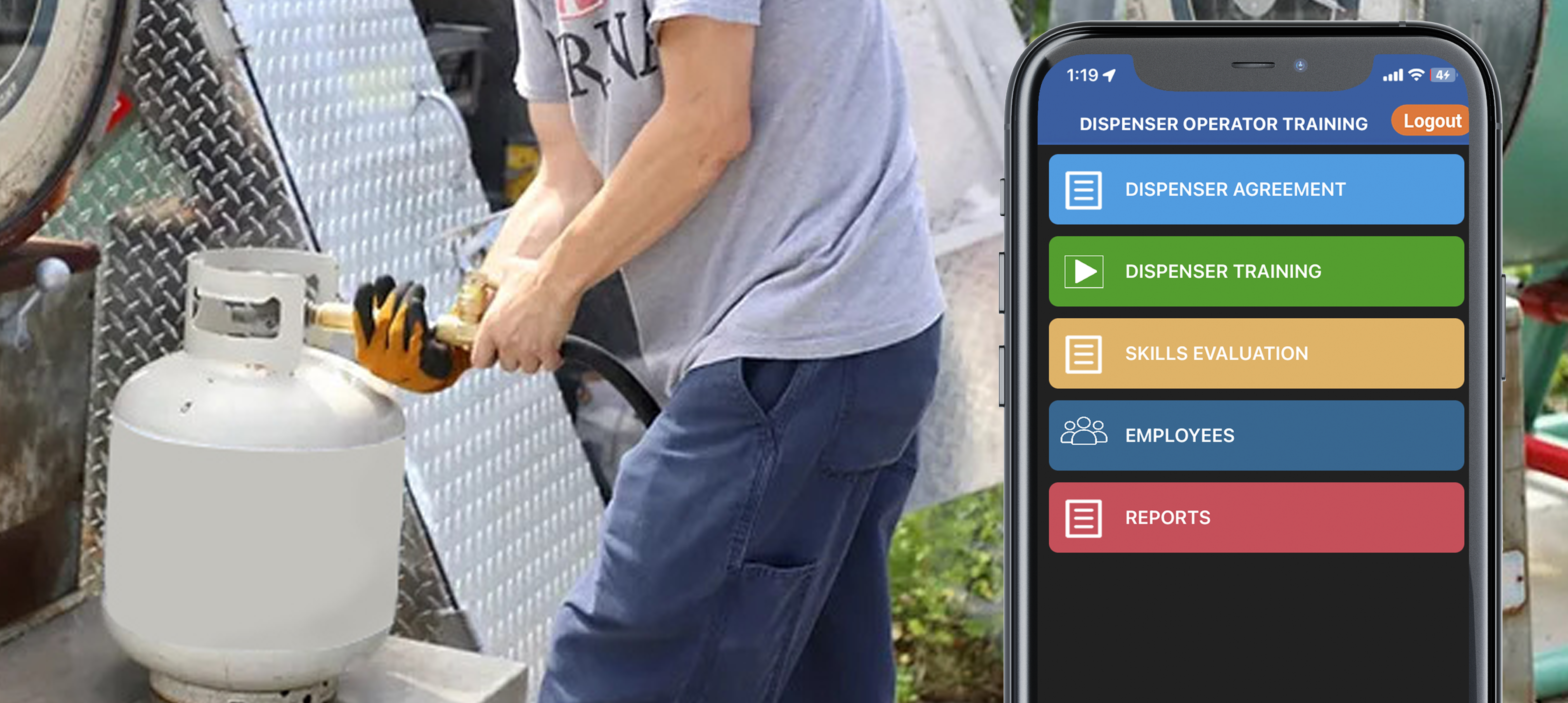

Expanding your retail offerings to include propane refilling isn’t just an add-on offering to your customers – it’s a smart business move. This service caters to a wide range of needs, from powering motor homes to fueling patio heaters, offering essential support to local businesses and households alike. Let’s take a look at both the… Continue reading The Lucrative Business of Propane Tank Refilling