Low Tech Profit Booster

Sometimes using low-tech tips and tricks to improve profits work great and cost nothing. There are some real gems that it seems very few companies are using. Those who are using this low-tech trick love it. Why? Because it saves them $150,000 upfront and then more each year.

Years ago, I scoffed at this “insider” trick. After doing the math, seeing it in action across dozens of other propane and fuel delivery companies, then using it in over 80 fuel operations of my own or with clients, we all agree that this is a fantastic, easy to use and effective “No/Low Tech” way to boost profits.

Better yet, when you too invest these “newly found” improved profits into High Tech tools, your earnings will get a double boost. “Save money in one place and reinvest it in high-tech tools for your business where it gets a 10X return”.

So what is the Low Tech trick? Simple… “It’s all in how you slice up the work week.”

A few years ago (in one of our colder winters), while at a client’s office, the owners shared that their spares were all out of action, and now one of their front-line fuel delivery trucks just went down too. It was cold, deliveries were stacking up fast, run-outs were imminent, and they had a severe fuel delivery truck shortage. We shared this trick with them, and not only were they able to handle the increased deliveries, prevent run-outs, and reduce payroll hours, that spring, they sold off one fuel delivery truck (banked the money). Since then, they have continued this trick, saving them tens of thousands of dollars yearly.

The trick is more straightforward than expected, yet it works great. It is a perspective change in how we approach the delivery schedule. It requires knowing how our delivery drivers operate and how we can better utilize their billable time. No, it may not work everywhere, but it works 95% of the time.

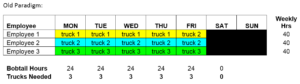

Most companies have their delivery drivers work 40-hour work weeks. Any more than that becomes over time. Most companies split the 40 hours over five work days – Monday through Friday. Then they usually have to pay more overtime for weekend deliveries. When you change their workday to Four 10hr days AND open the workday up to Monday through Saturday, several Fascinating things take place:

• You now can minimize overtime daily as you have drivers on duty a bit longer

• You can now minimize overtime on the weekend as you have a driver working Saturday as a regular occurrence

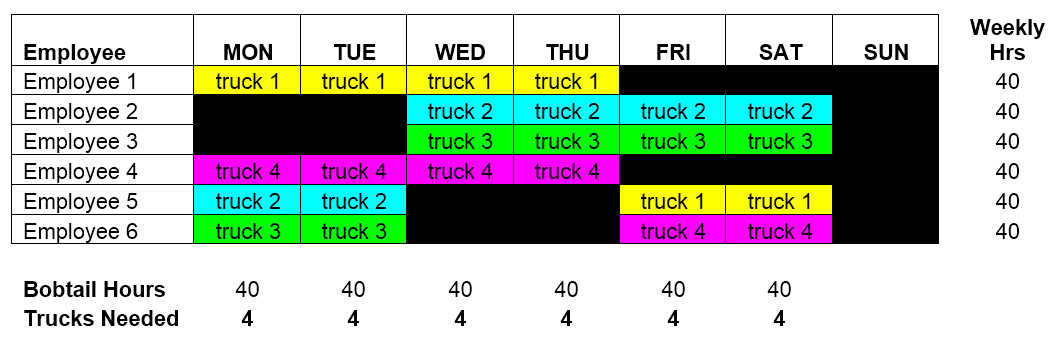

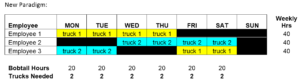

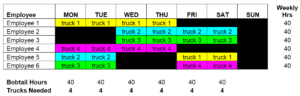

As each driver only needs 4 of the 10-hour delivery slots to fill their 40-hour requirement, you have 2 – 10 our slots available for a truck each week. Doing the math on two fuel trucks offers 12 total 10-hour weekly delivery slots. That is equal to the 12 scheduled delivery slots that three drivers need. So, in essence, you can prepare three drivers on two fuel trucks, as seen in the image below.

Benefits:

• Need 33% fewer fuel trucks – save $150,000+ on purchasing a new truck

• Less overtime on weekends and evenings – save money

• Drivers love 4-day work weeks – retain and attract better drivers

• You get 7.5 more delivery hours per week from each driver saving over $8,600 in payroll annually *see explanation at the bottom

• You get better asset (fuel truck) utilization and better Return On Investment for each fuel truck

• Better customer service by handling after-hours and weekend delivery emergencies faster.

•Take your extra truck and get it fully serviced so you can rotate our other front-line vehicles so they are always fully maintained with NO loss of delivery time.

It would be best if you had 50% more trucks compared to the new paradigm – very costly to purchase and maintain extra vehicles

• More Overtime costs

• Less flexible schedule.

• Drivers are accustomed to it but would prefer 4-day workweeks

A funny thing happens when you implement this flexible 4×10 workweek. First, it is new and different, so everyone is skeptical; I certainly was too. That’s “OK” and normal across every company. Next, the management (after a close study) realizes that this will save them tons of money, so they “buy in.” Then the drivers hear about it and consider it a “mutiny.” After convincing them to try it for a month, they finally figure out that they all get to work 4-day work weeks, so they get an extra day off each week… they fall in love with the schedule and threaten to “mutiny” if you dare change it back.

So, by now, you may be figuring out that you have six drivers and six front-line trucks – you only now need four and can “pass” on purchasing two replacement fuel trucks… true enough, you just tripped over $300,000.

*note: Most fuel delivery company drivers come to work, and during their first 30 minutes and last 30 minutes of the day, they are paid for doing paperwork (filling it out and delivering it), doing pre-trip and post-trip inspections, and doing the start of the day and end of the day “chit chat.” Also, every day, you pay them at some point for breaks and lunch breaks for around 30 more minutes. So, all told, you pay them for 90 minutes a day of unproductive work. If you have five drivers and could eliminate 90 min/week of the wrong time, you can save 7.5 hours of inefficient and unprofitable payroll expense at $23/hour, an annual savings of $8,625. This is one way that 4x10s help get more work per driver per week, lowering overtime and payroll costs.

I hope you, too, have fun with this. You, too, may find that this schedule works excellent in-season and off-season by the ocean/mountains/lakes/prairies. If you have any questions about how to implement this or would like our team to help you too get the extra $150,000 you deserve, then feel free to reach out to us at propanequarterback.com