Understanding Propane Regulator Lock-Up: Safety and Standards Explained

In residential propane systems, the concept of “lock-up” holds vital importance in ensuring safe and efficient operations. Lock-up occurs within regulators when the regulator’s orifice is entirely closed off, preventing the flow of propane through it.

Understanding the Mechanism

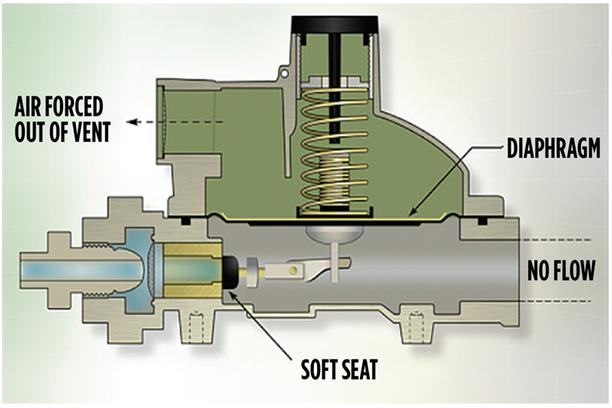

Lock-up is a result of the demand for propane downstream ceasing. As the pressure beneath the diaphragm builds up, it exerts force, compressing the main spring. This compression rotates the lever arm at the pivot point, causing the seat to press against the orifice, effectively stopping the flow of propane.

Verification and Testing

Service technicians verify lock-up by measuring the downstream pressure using manometers or pressure gauges. The test involves introducing propane flow into the system and shutting off the flow to all appliances downstream. The technician then monitors the pressure increase, ensuring it remains within acceptable limits. Companies typically establish protocols and limitations for this process.

Adherence to Standards

Regulator manufacturers adhere to UL Standard for Safety LP-Gas Regulators, UL 144, which outlines lock-up pressure limits based on regulator type, initial inlet pressure, initial outlet pressure setting, maximum inlet pressure, and lock-up pressure limit at maximum inlet pressure.

Consider a second-stage regulator as an example, with an inlet pressure of 10 psig and an outlet pressure setting of 11 in. water column (W.C.). Its lock-up pressure limit is set at 120 percent (13.2 in. W.C.), with a maximum inlet pressure of 15 psig and a maximum lock-up pressure of 160 percent (17.6 in. W.C.).

Safety Measures and Challenges

Pressure exceeding the limit can result from debris obstructing the orifice and the soft seat. Such obstructions prevent complete valve closure, impeding regulator lock-up. Initial installations often encounter piping debris, dirt, and excess thread sealant that can accumulate in the regulator. Removable screens at regulator inlets prevent debris from entering the orifice and seat disc assembly.

The regulator’s internal relief mechanism activates when lock-up isn’t achieved, and downstream pressure rises. An additional spring within the main spring triggers a passage to open when pressure surpasses its set point, providing safety against over-pressurization.

Importance of Lock-Up

Modern appliances equipped with electronic ignition differ from traditional standing pilot light appliances. Appliances with a pilot light constantly burn a small amount of propane, preventing regulator lock-up. However, non-pilot light appliances require lock-up after every shutdown to ensure uninterrupted propane flow.

For comprehensive education on regulator operation, including lock-up insights, the Propane Education & Research Council (PERC) provides valuable resources through its Learning Center. Understanding regulator lock-up is essential for maintaining safety, operational efficiency, and compliance with industry standards.